Aluminium window frames and handrail systems are becoming more popular because they are a cost-effective and durable option. This is because they can provide excellent design and aesthetic qualities that are hard to find in other materials. There are a variety of different aluminium window frame designs available, so it may be difficult to find the perfect one. Here are some important considerations when choosing an aluminium handrail railing profile:

The most common material used for an aluminium window frame and handrail system is aluminium. The most popular main material for an aluminium profile for either a door or window is aluminium. The most commonly used aluminium material for a doorframe is aluminium; the preferred main dimension of this profile for an exterior door frame is 2.0 mm; the preferred thickness of an aluminium window frame is 1.4 mm. All structural components of these systems have a very high degree of tolerance, which means the smaller the dimension, the better the aluminium railings are.... All aluminium products have a high degree of structural stiffness, which means the aluminium window frame can provide a great deal of support for heavier windows and doors without the need for excessive bracing. However, this means that aluminium products are not so well suited to applications where loads must be supported in a non-unchallised configuration. As such, these rails and handrails are not recommended for balconies, stairs and outdoor decking applications.

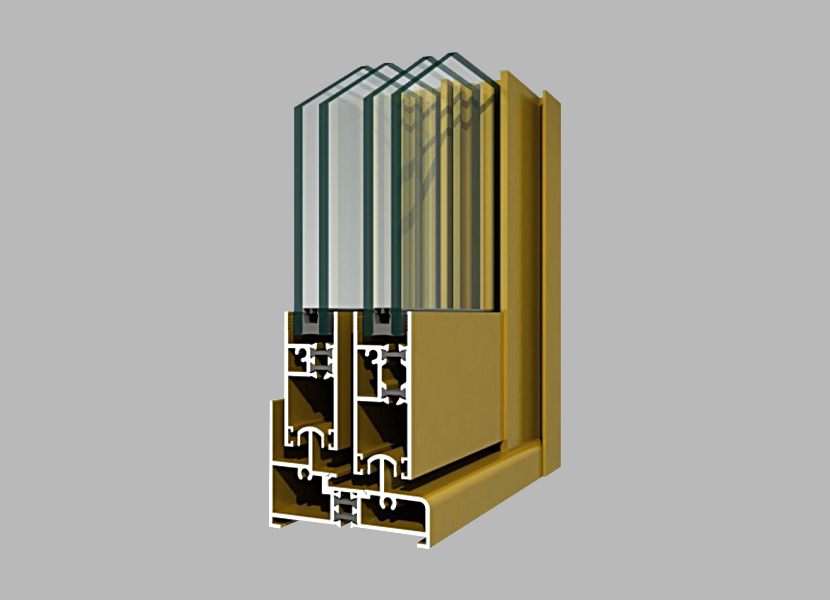

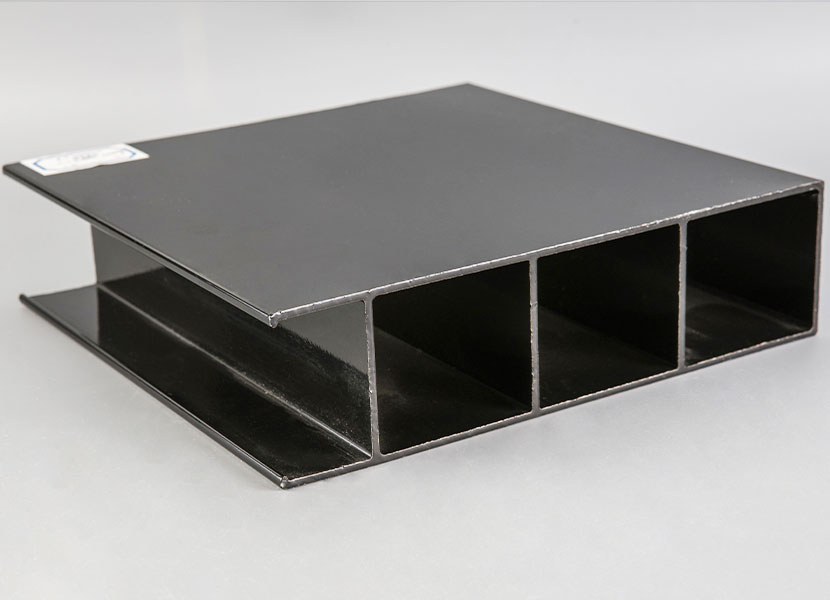

There are two aluminium window frame types that are most commonly found on buildings: the full aluminium window frame, also known as an 'armature' or 'armoured window' and the aluminium door extrusion. Full aluminium window frames are constructed with an extra, thicker top rail. The reason for this extra support is because the thicker top rail carries more weight, which means it will require more aluminium extrusion to create a strong frame; aluminium is generally more expensive than steel, but it's worth the extra expense in the long run as it usually lasts longer than steel. The disadvantage of full aluminium window frames is that they tend to look old quickly and need more maintenance than their aluminium counterparts.

An aluminium extrusion refers to the use of aluminium foils, either inside or outside of a window or door frame - they're usually placed inside the frame, on either side, to improve its appearance. Aluminium extrusion has many benefits, including the fact that it makes the window or door frame look lighter and more aesthetically appealing, but the downside is that it's much more costly than aluminium foils. The best aluminium extrusion products, which have an average film thickness of 0.2mm, are extremely resistant to rusting and denting. An aluminum extrusion also tends to be stiffer than a standard window or door frame, meaning that more of it can be used in the future to create the same type of product if desired.

Another method of improving the appearance of an aluminium window frame profile is to apply a surface treatment to the whole product. Spray coating is probably the most common of these treatments, as it's easy to apply, relatively inexpensive and doesn't require a large amount of labour to complete. Spray coatments can be applied to the surface of an aluminium window frame profile by a professional, or you could do it yourself using a paint sprayer or roller. The type of spray to use depends on what type of appearance you're trying to achieve. For example, water soluble surface treatment products will wash away more easily with water, and so are best used outdoors where the weather is likely to be moist. These types of products will also repel dust, meaning that your curtains will look clean even after you've drenched them.

An alternative option is to use a high quality aluminium extrusion powder coating product. These products will require a little bit of work to install, but will offer a far more professional finish than water soluble products. These aluminum extrusion powders will bond better to aluminium surface, meaning that they'll be harder to see when drenched. Powder coating products will also have far more defined colour choices, so can match curtain wall panels and louvers much more easily. You also won't have to worry about colour matching being too close or too far from each other as they'll be of similar intensity. These products are also more durable than their solvent-based alternatives, and will last many years before needing to be replaced.

English

English 简体中文

简体中文 España

España