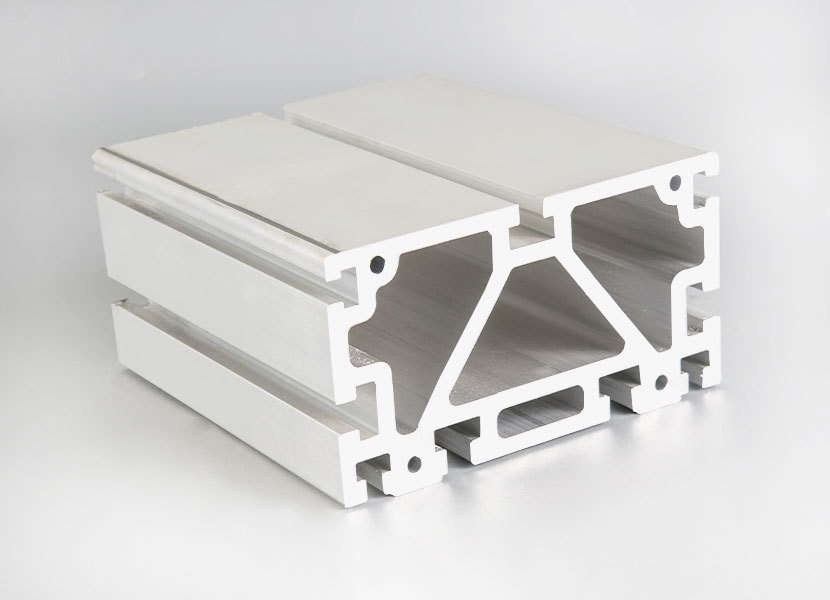

At present, industrial aluminum profiles are common materials in the production and life of modern society. Products made of aluminum and other alloying elements. Aluminum extrusion materials are usually aluminum rods that have undergone hot melting, extrusion and various surface treatments to obtain different cross-sectional shapes and appearances. Aluminum is the main metal element, and some alloying elements are added to improve the performance of aluminum. So what are the application areas of industrial aluminum profiles?

Compared with traditional materials such as iron and stainless steel, industrial aluminum profiles have the following advantages:

1. Industrial aluminum profiles only need to be designed, cut/drilled and assembled; however, traditional mechanical manufacturing materials usually undergo complex processes such as design, cutting/drilling, welding, sandblasting/surface treatment, and painting.

2. The frame using industrial aluminum profiles has no heat welding in the whole production process, so the parts can be easily disassembled, and all materials and accessories can be recycled and reused; however, due to cutting deformation and high disassembly costs, traditional mechanical manufacturing materials Rarely reused.

3. Due to the simple manufacturing process of industrial aluminum profiles, a lot of labor costs can be saved; especially when reworked due to manufacturing errors, it saves several times the man-hours compared to traditional mechanical manufacturing materials.

4. Industrial aluminum profiles are not thermally welded in the production process, and the material is not deformed, so the assembly accuracy is high; however, the traditional thermal welding machinery manufacturing materials will inevitably deform, thus affecting the assembly accuracy.

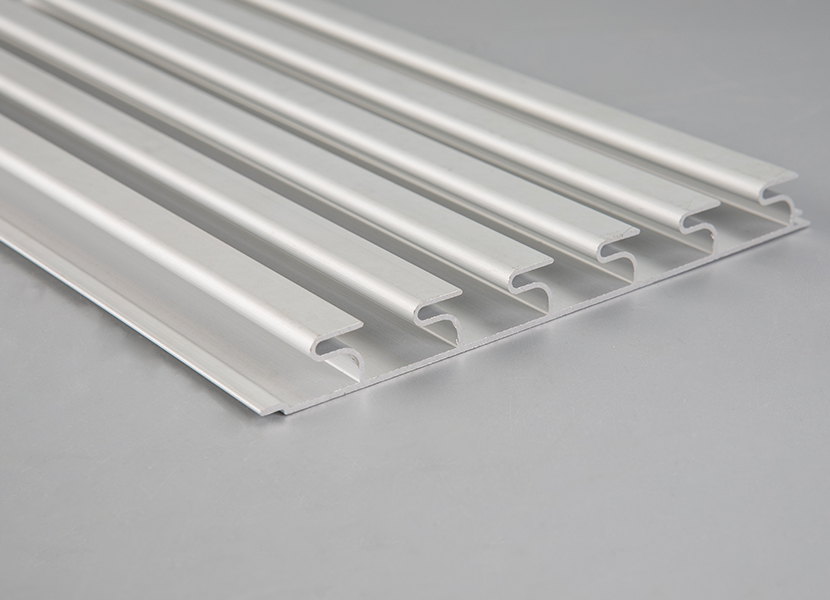

5. There are many varieties of aluminum profiles in the assembly line, complete specifications, moderate price, and wide application range; light unit weight, good mechanical properties, high connection strength, and large bearing capacity.

Dimensional specifications, strict tolerances, beautiful appearance, good finish, anti-corrosion; special use, no need for welding, more environmentally friendly, easy to install, disassemble, carry and transport.

7. The appearance of the equipment made of industrial aluminum profiles is more modern, and its anodized coating is stronger and more stable than the existing coating methods.

The application fields of industrial aluminum profiles are as follows:

1. According to the application field, industrial aluminum profiles refer to all aluminum profiles except building doors and windows, curtain walls, interior and exterior decoration and building structural aluminum profiles.

Aerospace aluminum profiles.

Making aircraft skins, fuselage frames, girders, rotors, propellers, mailboxes, siding and landing gear struts, rocket forging rings, spaceship siding, etc.

2. Aluminum for transportation.

It can provide various aluminum alloy materials for automobiles, large-scale porous profiles for subways and light rails, and meet the requirements of localization of subways. Engine components, air conditioners, radiators, body panels, wheel hubs and marine materials.

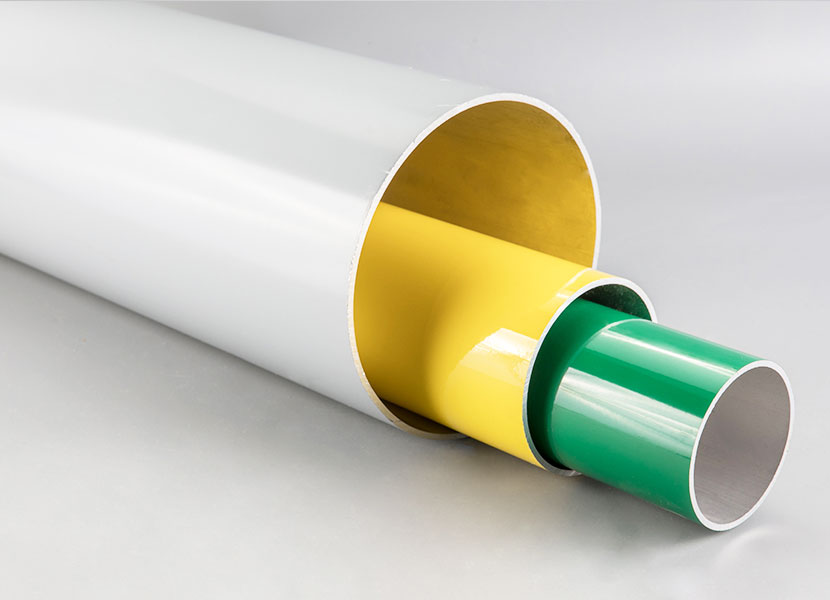

3. Aluminum packaging.

All-aluminum can is a sign to measure the level of aluminum processing in a country. Aluminum is mainly used as a metal packaging material in the form of sheets and foils, made into cans, lids, bottles, barrels and packaging foils. Widely used in packaging beverages, food, cosmetics, medicines, cigarettes, industrial products, etc.

4. Printed aluminum.

The printing industry bid farewell to "lead and fire" and entered the era of "light and electricity". Aluminum for printing is mainly used to make PS plates, and it is a new material in the printing industry for automatic plate making and printing. The aluminum-based PS plate provides a strong support for this change in the printing industry.

5. Aluminum for electronic appliances.

Mainly used in various busbars, wires, conductors, electrical components, refrigerators, cables and other fields. Aluminum foil for air conditioner has excellent deep drawing performance, high strength and good ductility, reaching the level of imported similar products; high-performance electrolytic capacitor foil. Specifications: Round and square bars, including aerospace fixtures, electrical fixtures and communications.

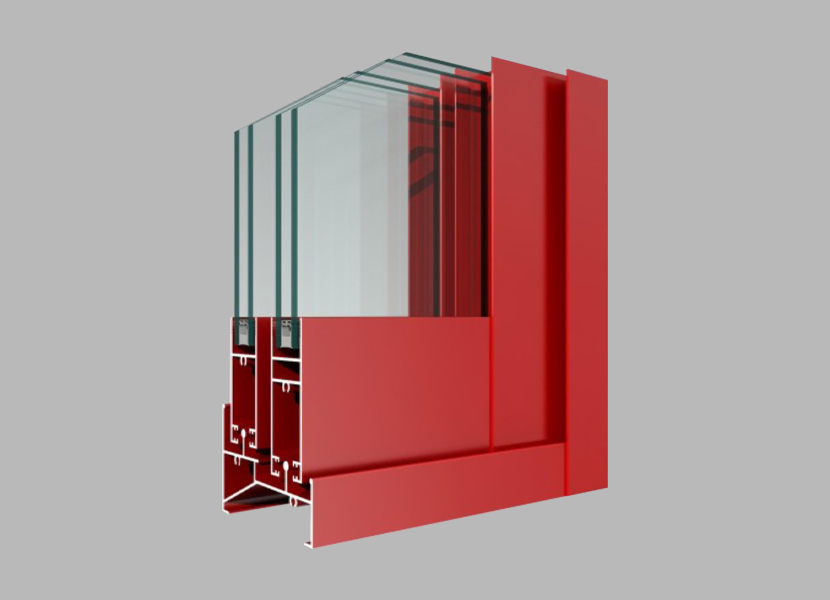

6. Aluminum for architectural decoration.

Because of its good corrosion resistance, sufficient strength, excellent process performance and welding performance, aluminum profiles are widely used in building frames, doors and windows, ceilings, decorative surfaces, etc. The construction industry is one of the three major markets for aluminum. The construction aluminum products are constantly updated, and the application of new construction products such as colored aluminum sheets, composite aluminum sheets, composite door and window frames, and aluminum alloy formwork is also increasing year by year. In industrial and civil buildings, my country has used aluminum alloys to make roofs, walls, doors and windows, etc., and gradually expanded to internal and external decoration, construction templates, etc., and achieved good results.

English

English 简体中文

简体中文 España

España