1. Pitting corrosion

Pitting corrosion, also known as hole corrosion, is a very localized corrosion form that produces needle-like, point-like and hole-like shapes on metals. Aluminium will undergo pitting corrosion in the atmosphere, fresh water, and neutral aqueous solutions. In severe cases, it can also lead to perforation, but the corrosion holes may eventually stop developing, and the amount of corrosion remains at a limit value. Pitting corrosion is a unique form of anodic reaction and is an autocatalytic process.

2. Galvanic corrosion

Galvanic corrosion is also a characteristic corrosion form of aluminum. The natural potential of aluminum is very negative. When aluminum is in contact with other metals, aluminum is always in the anode to accelerate the corrosion. Galvanic corrosion is also known as bimetallic corrosion, and the severity of corrosion is determined by the relative position of the two metal potential series.

3. Crevice corrosion

Crevice corrosion is the acceleration of corrosion in the crevice due to the action of the differential gas-filled battery, while there is no effect outside the crevice. Crevice corrosion has little to do with alloy type, and even very corrosion-resistant alloys can develop crevice corrosion. In recent years, the mechanism of crevice corrosion has been further studied, and the acidic environment at the top of the crevice is the driving force of corrosion.

4. Intergranular corrosion

Intergranular corrosion means that pure aluminum does not proliferate intergranular corrosion. The cause of intergranular corrosion is related to improper heat treatment. Alloying elements or intermetallic compounds are precipitated along the grain boundaries. Compared with the grains, the anode constitutes a corrosion cell, causing intergranular corrosion. Corrosion accelerates.

5. Filiform corrosion

Filamentous corrosion is a kind of sub-film corrosion, which develops under the film in a worm-like manner. This film can make the paint film and other layers, and generally does not occur under the anodized film.

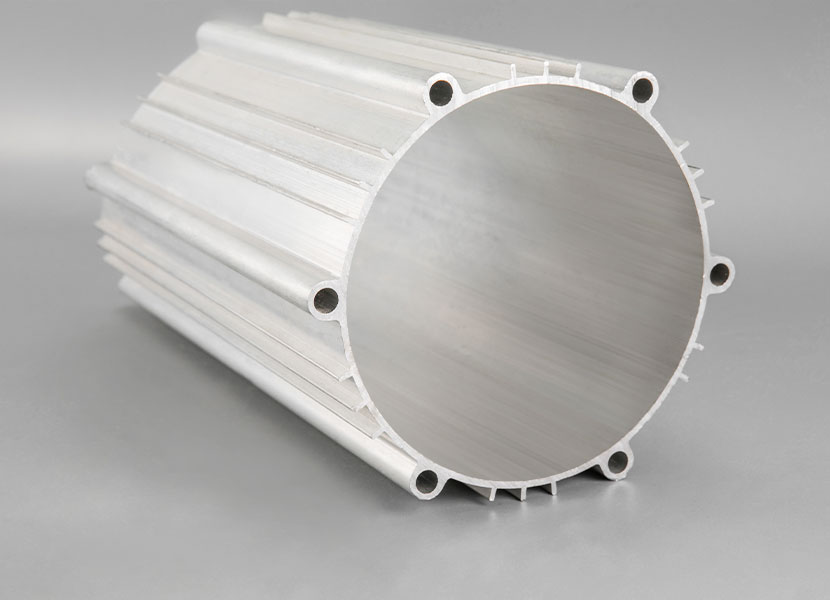

Zhejiang SUNKEY Industrial Co., Ltd. Is located in Yuyao,Ningbo city of eastern Zhejiang.As a professional Aluminium Section Manufacturers and Aluminium Section suppliers, the introduction of today's advanced production, quality control equipment, and built a set of casting, extrusion, anodizing, electrophoresis, powder coating, wooden in one of the large-scale professional aluminum manufacturing plant. We have our own foundry workshop, so we can offer good price and wholesale aluminium section. Annual production capacity of 45000 tons, the products include construction material, industrial material two series, nearly a thousand kinds of specifications, and specially designed for the customer to customize a variety of specific-type construction or industrial materials.

English

English 简体中文

简体中文 España

España