In recent years, the application of aluminum alloy materials in our lives is very common. The processing of aluminum profiles is indispensable for the development of the surface treatment process. If the surface treatment process cannot be carried out smoothly, it will affect its quality. What are the commonly used surface treatment processes for aluminum materials? Understanding these is also to ensure the quality of our aluminum alloy products. After all, there are various processes that can be used now. There are mainly three kinds of surface treatment processes commonly used for aluminum materials. By the surface treatment of aluminum alloy, we will introduce several treatment processes to you.

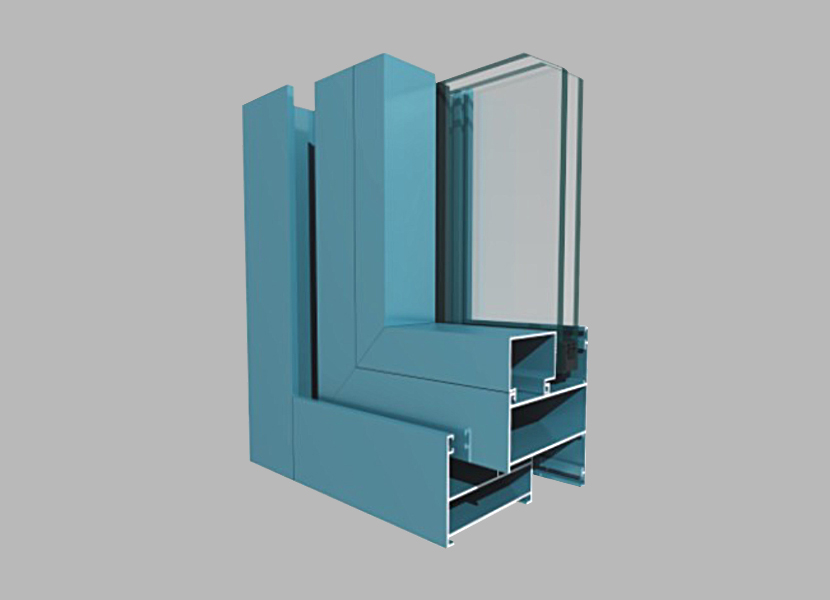

1. Electrophoretic coating

On the basis of anodization, through the action of electrophoresis, a layer of the water-soluble acrylic paint film is evenly covered on the oxide film, so that a composite film of anodized film and acrylic paint film is formed on the surface of the profile. The hand feels smooth and delicate, and the appearance is bright and bright. In addition to the color of the original oxidation coloring, it can make more bright colors such as white and green.

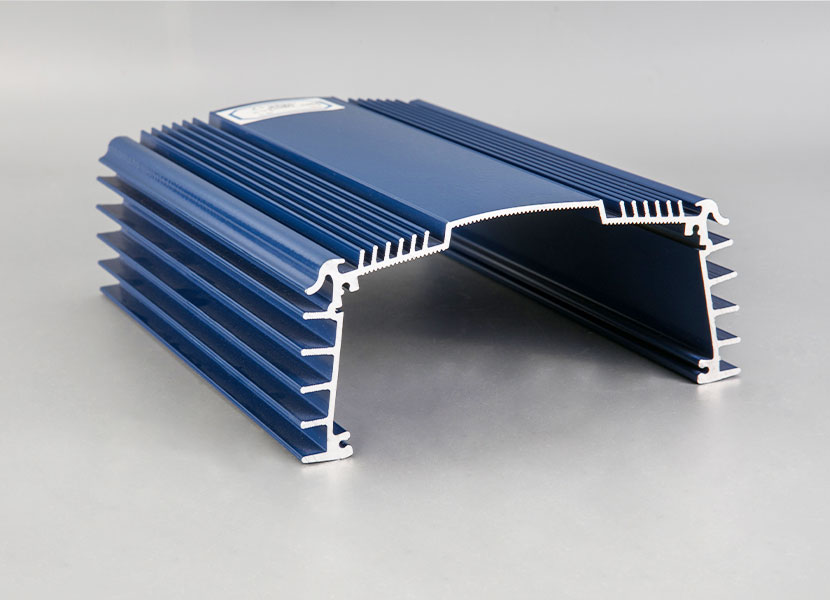

2. Color powder coating

A total of more than 200 color options, stable performance, strong paint film adhesion, not easy to peel off, acid resistance, salt spray resistance, weather resistance, aging resistance, and other properties. The coating is non-volatile, non-oxidizing, and toxic in the air, and has good environmental protection performance.

3. Color fluorocarbon spraying

The surface of the aluminum alloy substrate is sprayed with a polyvinylidene fluoride paint coating by electrostatic action. Fluorocarbon coatings are polyvinylidene fluoride, fluorocarbon coatings. Therefore, it can have long-lasting color retention, anti-corrosion, anti-air pollution, and its fluorocarbon bond is one of the strong molecular bonds in its molecular structure of polymerization. As a surface coating process, fluorocarbon spraying has the advantages of uniform color and resistance to fading and contamination.

English

English 简体中文

简体中文 España

España